Fleck 2510 Manual: A Comprehensive Guide

Bellevue’s diverse culinary landscape mirrors the Fleck 2510’s versatility, offering solutions for varied water needs․ Like finding the perfect restaurant,

understanding your water softener is key․ This guide, updated November 2025, provides essential information for optimal performance, mirroring Bellevue’s dynamic scene․

Understanding the Fleck 2510 System

The Fleck 2510 system is a widely utilized, reliable water softening solution, much like Bellevue’s diverse restaurant scene caters to many tastes․ It’s designed for residential applications, effectively removing hardness minerals – calcium and magnesium – from your water supply․ This process prevents scale buildup in pipes and appliances, extending their lifespan and improving efficiency, similar to how consistent quality ensures a restaurant’s success․

At its core, the system operates on an ion exchange principle․ Hard water flows through a resin bed, where hardness minerals are exchanged for sodium or potassium ions․ The Fleck 2510’s control valve orchestrates this process, initiating regeneration cycles to replenish the resin bed with salt brine․ Understanding these cycles – backwash, brine draw, rinse, and refill – is crucial for optimal performance, akin to a chef mastering various cooking techniques․

The system’s adaptability is a key strength, allowing customization of regeneration frequency and salt dosage based on water hardness and usage․ This flexibility ensures efficient operation and minimizes salt consumption, mirroring Bellevue’s restaurants adapting menus to seasonal ingredients․ Proper understanding of these features unlocks the full potential of the Fleck 2510, providing consistently soft water for your home․

Key Components and Their Functions

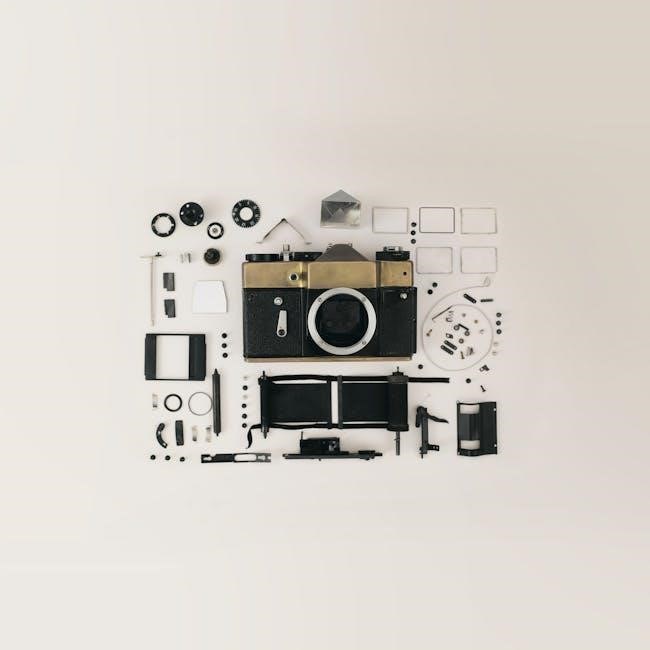

The Fleck 2510 system comprises several vital components, each playing a distinct role, much like a restaurant’s kitchen relies on specialized stations․ The control valve is the brain, orchestrating regeneration cycles and managing water flow – akin to a head chef coordinating service․ The resin tank houses the ion exchange resin, where water softening occurs, comparable to a pantry storing essential ingredients․

The brine tank stores the salt solution used to regenerate the resin, functioning like a restaurant’s beverage station․ A crucial element is the injector, creating the suction during the brine draw cycle, similar to a pump circulating sauces․ The drain line expels wastewater during regeneration, analogous to a kitchen’s waste disposal system․

Finally, the air check prevents backflow into the salt tank, ensuring proper brine draw, like a safety mechanism in a kitchen․ Understanding each component’s function is paramount for effective troubleshooting and maintenance, mirroring a restaurant staff’s knowledge of their roles․ Regular inspection and care of these parts guarantee optimal system performance and longevity․

Initial Setup and Installation

Proper installation is crucial for the Fleck 2510’s performance, much like a restaurant’s layout impacts service efficiency․ Begin by selecting a suitable location – a dry, level surface near a drain and water supply․ Ensure adequate space for maintenance, mirroring a kitchen’s need for accessibility․ Connect the water supply, following local plumbing codes, similar to adhering to health regulations․

Next, connect the drain line, ensuring a proper air gap to prevent back-siphonage, akin to a kitchen’s sanitation protocols․ Fill the brine tank with water and salt, observing recommended levels, comparable to stocking a pantry․ Power up the control valve, verifying correct voltage, like activating kitchen appliances․

Before initial operation, flush the system to remove any debris, mirroring a restaurant’s pre-service cleaning․ Program the control valve with your water hardness settings (detailed later), similar to setting menu pricing․ A careful, methodical installation ensures years of reliable operation, just as a well-planned restaurant setup guarantees smooth service․

Programming the Fleck 2510 Control Valve

Programming the Fleck 2510 is akin to customizing a restaurant’s menu – tailoring it to specific needs․ Access the programming mode by pressing and holding the ‘Program’ button, similar to accessing a restaurant’s POS system․ Navigate using the up and down arrow keys, mirroring scrolling through menu options․

First, set the time of day for accurate regeneration scheduling, like setting kitchen timers․ Input your water hardness level, obtained from a water test, comparable to sourcing quality ingredients․ Configure the regeneration cycle time, considering water usage, similar to adjusting prep times․

Customize salt dosage based on water hardness and resin capacity, mirroring portion control․ Program the backwash cycle duration, ensuring effective resin cleaning, like maintaining kitchen hygiene․ Save your settings and exit programming mode, similar to finalizing a menu․ Accurate programming optimizes performance and extends the system’s lifespan, just as a well-managed menu boosts a restaurant’s success․

Understanding the Control Panel Interface

The Fleck 2510 control panel, much like a restaurant’s order screen, is your central hub for system operation․ The display shows current status – service, regenerating, or in standby, similar to order status updates․ The ‘Program’ button initiates programming mode, akin to accessing administrative settings․

Up and down arrow keys navigate menus and adjust settings, mirroring scrolling through options․ The ‘Regenerate’ button manually initiates a regeneration cycle, like a chef starting a new dish․ A ‘Bypass’ function allows water flow without softening, comparable to a restaurant temporarily removing an item from the menu․

Error codes displayed indicate potential issues, similar to error messages on a POS system․ Familiarize yourself with these codes for quick troubleshooting․ The interface is designed for intuitive operation, allowing easy monitoring and control of your water softening system, just as a user-friendly interface enhances restaurant efficiency․

Setting Up Regeneration Cycles

Regeneration cycles, like a restaurant’s prep work, are crucial for maintaining optimal performance․ The Fleck 2510 allows customizable cycles based on water usage and hardness, mirroring a restaurant adjusting recipes based on ingredient quality; You’ll set a regeneration frequency – daily, every other day, or based on gallons used․

Time-based regeneration initiates at a specific hour, similar to scheduled kitchen tasks․ Volume-based regeneration triggers after a pre-set water usage, like restocking ingredients after a busy service․ Consider your household’s water consumption when choosing a method․

Regeneration involves backwash, brine draw, slow rinse, and fast rinse – a sequence akin to a multi-step cooking process․ Proper setup ensures efficient resin cleaning and consistent water softening․ Regularly review and adjust these settings based on water quality reports, ensuring your system operates like a well-managed kitchen․

Adjusting Salt Dosage

Salt dosage, much like seasoning in a Bellevue restaurant, is critical for optimal flavor – or, in this case, water softening․ The Fleck 2510 allows precise adjustment of salt usage during the brine draw cycle, ensuring efficient resin regeneration without waste․ Incorrect dosage can lead to hard water or excessive salt buildup․

Start with the manufacturer’s recommended setting based on your water hardness level․ Monitor your softened water regularly using a test kit, similar to a chef tasting a dish․ If hardness persists, incrementally increase the salt dosage․ Conversely, if you notice salt bridging or a salty taste, reduce the dosage․

Consider the salt type used; rock salt requires different settings than evaporated salt․ Regularly inspect the brine tank for proper salt levels and dissolution․ Fine-tuning the salt dosage ensures efficient operation, mirroring a chef’s precise adjustments for a perfect culinary experience․

Backwash Settings and Optimization

Optimizing backwash settings on your Fleck 2510, akin to a Bellevue chef perfecting a recipe, is crucial for maintaining system efficiency․ The backwash cycle removes accumulated sediment and debris from the resin bed, preventing channeling and ensuring consistent softening․ Default settings often suffice, but adjustments may be needed based on your water quality․

Consider the backwash duration; longer cycles provide more thorough cleaning but consume more water․ Shorter cycles conserve water but may not adequately remove all contaminants․ Observe the backwash discharge – clear water indicates effective cleaning, while cloudy water suggests insufficient duration or flow rate․

Adjust the backwash initiation frequency based on sediment levels․ If you experience frequent pressure drops, increase the frequency․ Regularly monitoring and adjusting these settings, much like a restaurant adapting to customer preferences, ensures peak performance and longevity of your Fleck 2510 system․

Brine Tank Maintenance

Maintaining your Fleck 2510’s brine tank, similar to a Bellevue restaurant maintaining its kitchen, is vital for consistent operation․ The brine tank stores the salt solution used for resin regeneration․ Regular inspection prevents issues like salt bridging and tank clogging, ensuring efficient softening․

Periodically check the brine tank for salt crusting or buildup․ A salt bridge – a hard layer of salt forming over the water – can prevent proper brine draw․ Break up any bridges with a tool, avoiding damage to the tank․ Ensure the brine well remains clear of debris․

Clean the tank annually, removing any accumulated sediment or sludge․ This prevents clogging and maintains optimal brine production․ Like a well-maintained establishment, a clean brine tank contributes to the overall health and longevity of your Fleck 2510 system, mirroring Bellevue’s commitment to quality․

Troubleshooting Common Issues

Like navigating Bellevue’s diverse dining options, resolving Fleck 2510 issues requires a systematic approach․ Common problems include low water pressure, often due to sediment buildup or a clogged injector․ Inspect and clean these components regularly, mirroring the upkeep of a bustling restaurant kitchen․

Salt bridge formation, as previously discussed, hinders regeneration․ Address this promptly by breaking up the bridge and ensuring proper salt dissolution․ Valve leakage can indicate worn seals or O-rings, requiring replacement․ Ignoring these issues can lead to inefficient softening and increased water usage․

If problems persist, consult the official Fleck manual or seek professional assistance․ Just as Bellevue residents rely on trusted establishments, you can depend on qualified technicians for complex repairs․ Proactive maintenance and timely troubleshooting ensure your system operates smoothly, providing consistently soft water․

Low Water Pressure Problems

Experiencing reduced water pressure with your Fleck 2510 system, much like a delayed dinner service in Bellevue, requires immediate attention․ The primary culprit is often sediment buildup within the control valve or resin tank․ Thoroughly inspect and clean the injector, ensuring it’s free from debris – a crucial step, similar to maintaining a restaurant’s clean water lines․

A partially clogged resin bed can also restrict flow․ Initiate a manual backwash cycle to dislodge accumulated particles․ Verify that the bypass valve is fully open, allowing unrestricted water flow․ Check for kinks or obstructions in the plumbing lines connected to the system, mirroring a chef ensuring clear pathways in the kitchen․

If the issue persists, examine the inlet and outlet screens for blockage․ Consistent low pressure signals a deeper problem, potentially requiring professional evaluation․ Addressing these issues promptly restores optimal water flow and system efficiency․

Salt Bridge Formation

Salt bridge formation within the brine tank, akin to unexpected delays in Bellevue’s bustling food scene, is a common Fleck 2510 issue․ This hard crust prevents brine water from being drawn into the system for regeneration, impacting water softening performance․ Regularly inspect the brine tank for salt buildup, especially after periods of inactivity – much like a restaurant checking ingredient freshness․

To resolve a salt bridge, carefully break it apart using a broom handle or similar tool, avoiding metal implements that could damage the tank․ Ensure proper salt type is used; rock salt is generally recommended․ Maintaining adequate humidity within the brine tank can prevent future bridging․ Consider adding a small amount of water directly to the salt pile to encourage dissolution․

Consistent monitoring and preventative measures, similar to a restaurant’s quality control, are key to avoiding salt bridge formation and ensuring efficient system operation․

Valve Leakage and Repair

Valve leakage in a Fleck 2510 system, much like an unexpected service disruption in Bellevue’s dining establishments, requires prompt attention․ Leaks can manifest around the control valve body, seals, or connections, leading to water waste and potential damage․ Initial inspection should focus on identifying the leak’s source – a methodical approach, similar to a chef diagnosing a dish’s flaw․

Minor leaks may be resolved by tightening connections or replacing O-rings and seals․ However, significant or persistent leaks often indicate a more substantial issue, potentially requiring control valve component replacement․ Always disconnect power and water supply before attempting repairs․ Refer to the official Fleck manual for detailed disassembly and repair instructions․

If repairs prove challenging, consulting a qualified plumbing professional is recommended, ensuring efficient and safe resolution, mirroring the expertise found in Bellevue’s top restaurants․

Replacing the Control Valve

Replacing the control valve on a Fleck 2510 system, akin to a restaurant undergoing a complete renovation, is a significant undertaking․ It’s typically reserved for situations where repairs are impractical or the valve is severely damaged․ Before commencing, ensure you have the correct replacement valve – verifying compatibility is crucial, much like confirming a restaurant’s menu aligns with customer preferences․

Begin by disconnecting the power and water supply․ Carefully disconnect all tubing and electrical connections, labeling them for reassembly․ Remove the old valve, noting its orientation․ Install the new valve, ensuring proper alignment and secure connections․ Reconnect all tubing and electrical wiring, referencing your labels․

Post-installation, thoroughly test for leaks and proper operation; Programming may be required to match your original settings․ If unsure, consult a qualified plumber, mirroring the expertise of Bellevue’s culinary professionals․

Winterizing the Fleck 2510 System

Preparing your Fleck 2510 for winter, similar to Bellevue restaurants adapting seasonal menus, is vital to prevent damage from freezing temperatures․ Begin by turning off the water supply to the system and disconnecting the power․ Drain all water from the softener tank, brine tank, and control valve․ This includes manually flushing the system to remove residual water, much like clearing a restaurant’s kitchen at closing․

Bypass the softener and drain the plumbing lines leading to and from the unit․ Add RV antifreeze to the brine tank – never use automotive antifreeze․ Run a short regeneration cycle with the antifreeze to protect the internal components․ Ensure all connections are secure and insulated where possible․

Re-establish power only when preparing to use the system again in the spring, mirroring a restaurant reopening after a seasonal closure․

Where to Find Official Fleck Manuals and Support

Locating official Fleck 2510 resources is as crucial as finding reliable restaurant reviews for Bellevue dining – ensuring accuracy and satisfaction․ The primary source for comprehensive manuals is the Pentair Residential Solutions website (formerly Fleck)․ Here, you can download PDF versions of installation guides, owner’s manuals, and parts lists, mirroring the detailed menus offered by Bellevue’s diverse eateries․

Additionally, numerous online plumbing supply retailers host downloadable manuals․ Direct support can be obtained through Pentair’s customer service channels, including phone and email․ Online forums and communities dedicated to water treatment often provide valuable troubleshooting tips and peer support, similar to online dining communities․

Remember to verify the manual’s version corresponds to your specific 2510 model for accurate information․